At Custom Magnetics, we manufacture a variety of transformers for audio equipment and medical devices, where precision is crucial and unnecessary noise has to be reduced to ensure optimal performance. Typically, for applications like these, our customers require R-core transformers, a unique type of transformer designed to almost eliminate leakage and in turn, improve the assembly’s efficiency and performance. However, R-core transformers do tend to be more expensive than other more common types, like the El-core transformer. In this article, we’re going to take a look at whether that higher cost is worth it, especially when performance is utmost.

An Overview of Each Type

El-Core

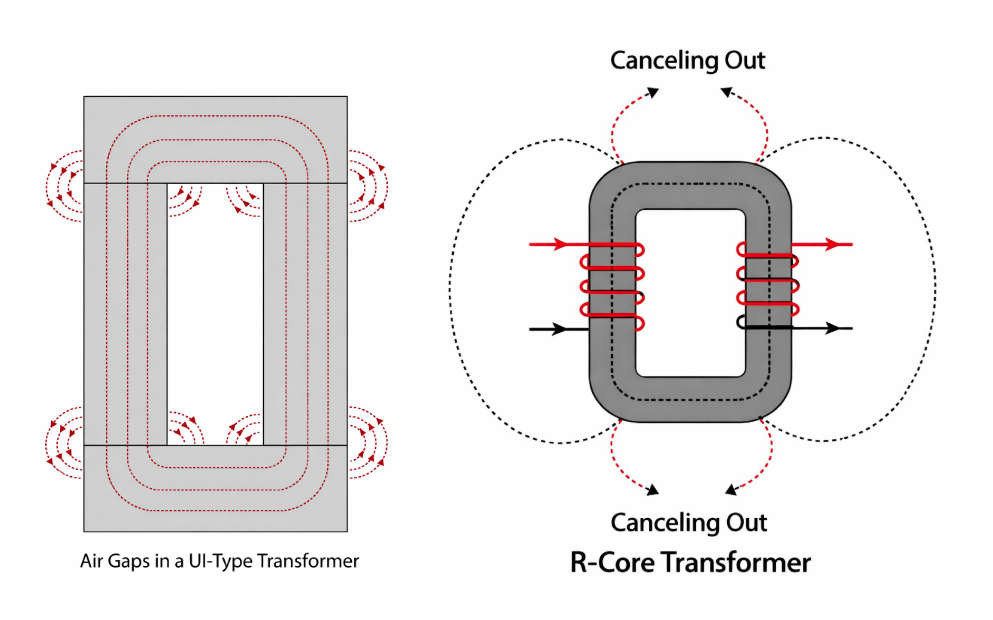

El-core transformers are the most common type of AC power transformer, and named for the shape of its laminated iron core. However, despite being traditionally a common and cost-efficient choice of transformer, the El-core design features several gaps between the laminations, allowing magnetic flux to leak out of the core, causing noise disturbances that could ruin a system’s overall precision or audio quality. This leakage can be mitigated by additional components, like a conductive flux band which helps to contain the flux, but doesn’t entirely solve the problem.

R-Core

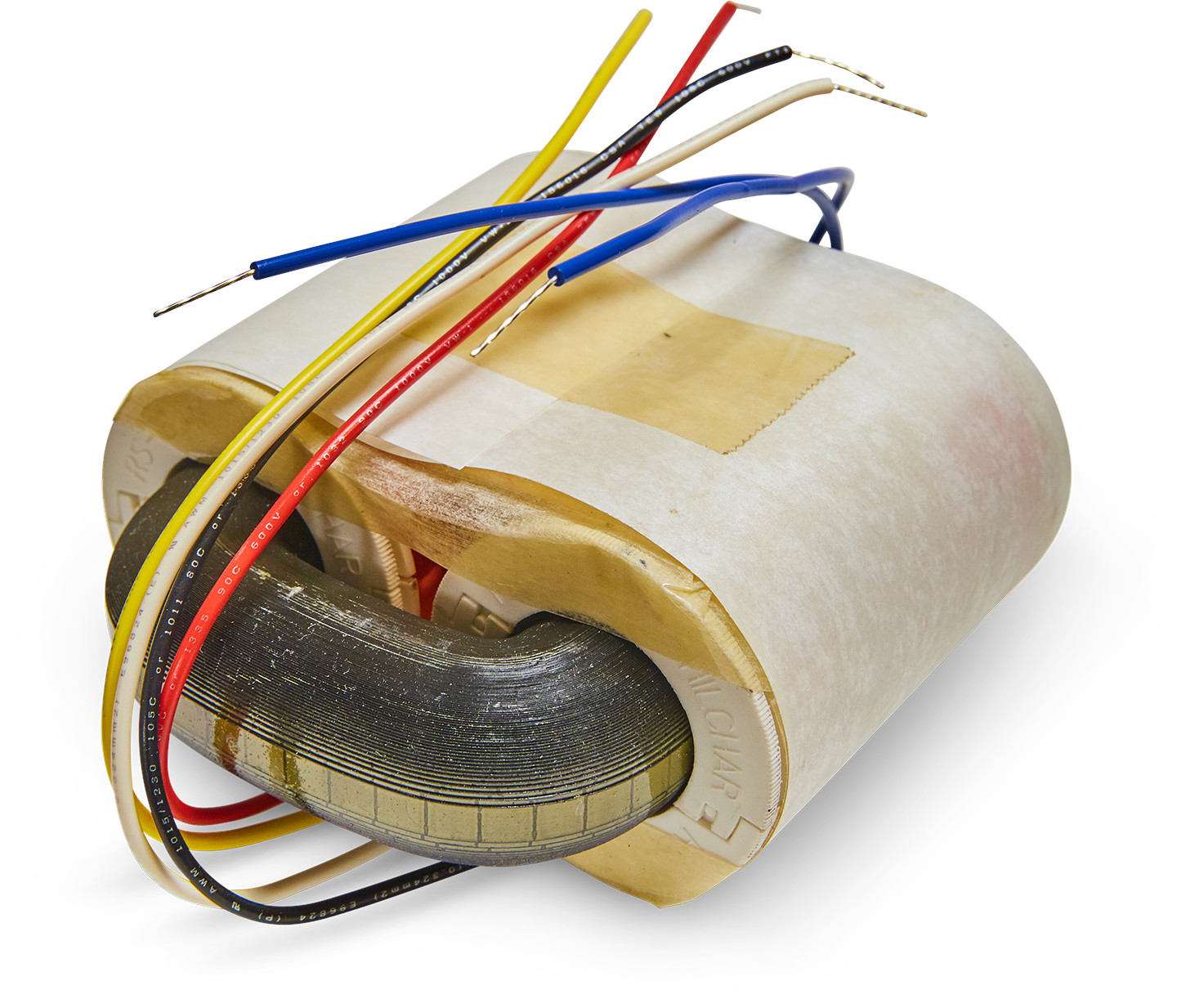

R-core transformers are a relatively newer type of transformer. These transformers feature a continuous metal strip of silicon steel that looks a little like a rectangle with rounded corners. The coils are wound on either long side of that rectangular core, offering a balanced and symmetrical winding on each side. The more identical those windings, the less leakage flux that occurs because those two winds essentially cancel out each other’s magnetic flux–a bit like balancing two identical weights on either side of a scale. Though generally more expensive to make due to the experience and precision necessary to actually make them work, R-core transformers almost entirely eliminate leakage.

A Side by Side Comparison of R-Core and El-Core Transformers

The table below offers a comparison of each transformer type and their more important characteristics.

| R-Core | El-Core | |

| Leakage Flux | Due to the balanced winding and the lack of air gaps in the core, R-Core transformers experience little to no leakage and rarely require shielding. | El-Core transformers have inherent air gaps and an unbalanced winding, so leakage is common. Additional shielding must be added to reduce and contain leakage |

| Exciting Current | R-core transformers do not need more exciting current due to the lack of air gaps in the core. | El-core transformers require more exciting current in order to overcome the inherent gaps within the materials that make up the core. |

| Versatility and Assembly | R-core transformers have a thin, light-weight design that offers several mounting options, making them excellent for high-precision and high-performance devices where weight reduction is a must. However, windings require technical expertise and specialized equipment. | El-core transformers are bulkier and heavier, and tend to take up more space in the assembly, but are typically cheaper and easier to manufacture and can be used in applications where precision isn’t as important as cost. Mounting options are more limited, but require less specialized equipment to achieve. |

| Efficiency | R-core transformers are naturally very efficient, with minimal core losses and additional noise. | El-core transformers offer an average performance with significant leakage, though their efficiency can improve with proper shielding. |

While R-core transformers offer excellent performance, especially in high-precision applications like high-end audio equipment and medical devices, they are not always the best choice for every project. Due to their higher manufacturing costs and specialized design requirements, R-core transformers are ideal for projects where performance and minimal leakage are paramount. However, for many other applications—especially those where cost is a significant concern—El-core transformers remain a reliable, cost-effective solution. Their simplicity in design and manufacturing make them an attractive option for applications where minor leakage and noise aren’t detrimental to performance.

About Custom Magnetics, Inc.

At Custom Magnetics, we have the expertise to help you select the right transformer for your specific needs, whether you require the precision of an R-core or the value and versatility of an El-core. We work with you to tailor our designs and deliver the best possible solution for your application.