Most projects can live with a catalog or general transformer design, but some can’t. Tight noise limits, unusual envelopes, tough environments, or non-standard frequencies push you beyond “good enough.” That’s where a custom rather than general transformer design pays for itself—and where core material and lamination strategy (M6, M29, M50, 80% nickel, ferrite, R-core, toroid) become major levers alongside winding topology and geometry.

Below is a clear, engineer-friendly way to decide whether standard or custom is best for your project—and what working with Custom Magnetics, Inc. (CMI) adds.

When a standard transformer is fine

- Reasonable leakage and capacitance are acceptable

- Size and mounting are flexible

- Ambient and isolation needs are ordinary

- Lifecycle/obsolescence risk is low

If that’s you, a catalog part may be the fastest route.

When a custom transformer pays for itself

If any of the following sounds like your application, then you’ll likely want a custom transformer:

- Noise or bandwidth targets are tight

- We tune winding topology (interleaving, sectional layers, shields, split primaries, foil or Litz) to place leakage inductance and interwinding capacitance where your circuit needs them.

- Harsh or regulated environments

- Reinforced insulation systems, creepage/clearance, altitude derating, potting/encapsulation, IP sealing, medical leakage limits—designed-in from day one.

- Thermals and efficiency

- Wire gauge, turns-per-layer, window utilization, flux density, and core choice balanced to meet temperature rise and loss goals—rather than discovering hot spots during validation.

- Geometry drives performance

- Custom bobbins, unusual envelopes, low-profile packages, multi-secondary routing, PCB integration, and mechanical decoupling to control hum.

- Non-standard frequencies

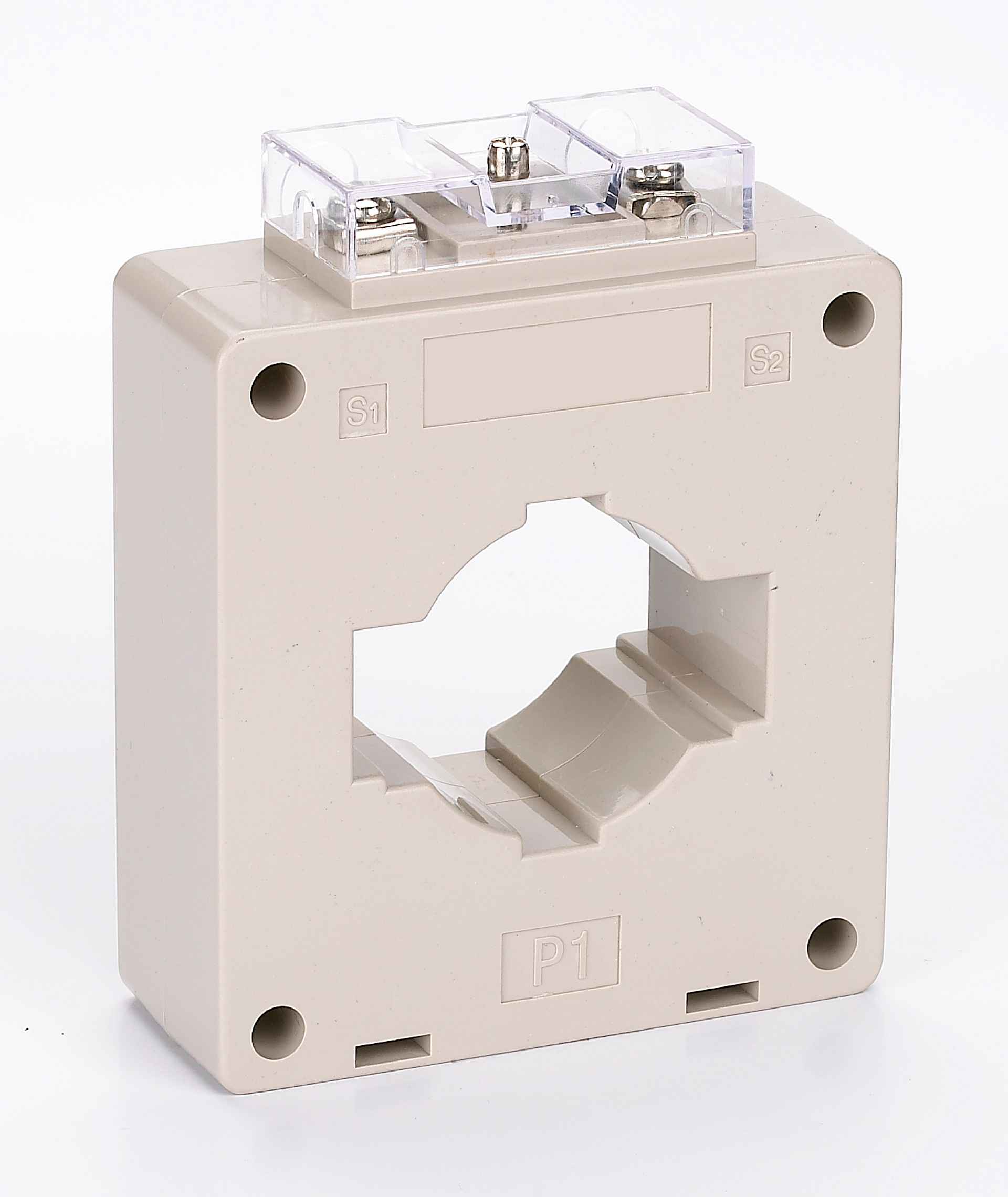

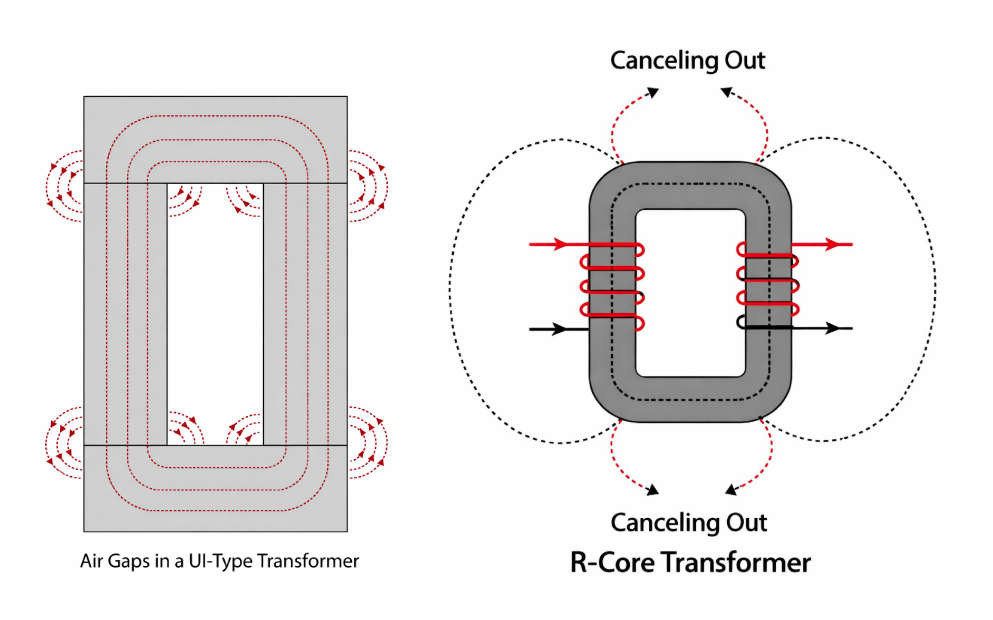

- From 50/60 Hz silicon steel to higher-frequency power electronics; R-cores for ultra-low stray field in audio/medical; ferrites for SMPS; toroids for high utilization and low leakage.

Core material & lamination strategy (the “why” behind M50 vs M6 vs M29 vs 80% Ni)

Core choice is not an afterthought. It sets magnetizing current, loss, headroom to saturation, mechanical hum, and cost.

- M6 (grain-oriented, ~0.014 in / 29-gauge typical)

- Low core loss along the rolling direction, high permeability, strong choice for mains-frequency power and low-hum audio power when efficiency and thermal margin matter.

- M27 / M29 / M36 (non-oriented silicon steels)

- More isotropic flux handling (no preferred direction), generally higher loss but lower cost than M6. Good for multi-axis flux paths (certain EI geometries, gapped chokes) and when cost/availability lead.

- M50 (economy non-oriented)

- Highest loss / lowest cost in this set; acceptable where duty cycle is low, temperature rise is forgiving, or price is the primary driver (pilot builds, cost-sensitive chokes/inductors).

- 80% Nickel (high-Ni alloys)

- Very high permeability, very low magnetizing current, and low distortion at small signals; lower saturation flux than steels. Excellent for audio signal transformers, instrumentation, low-level sensors—not for high-power mains delivery.

- Lamination thickness (29 vs 26 vs 24 gauge)

- Thinner laminations reduce eddy currents and core loss at 50/60 Hz and up, at added cost. Thicker laminations are cheaper but run warmer and noisier at the same flux.

- Magnetostriction & acoustic hum

- Grain-oriented M6 and 80% Ni can reduce buzz at sensible flux densities; non-oriented steels tend to hum more at the same B.

Bottom line: We pick material + thickness + geometry to hit loss, noise, and cost targets—not just “what’s on the shelf.”

How CMI designs (calculation-first, experience-backed)

- Math before metal: We size flux density, window utilization, wire gauge, predicted temperature rise, leakage inductance, and interwinding capacitance up front—so the first build behaves like the spreadsheet.

- Five decades of pattern recognition: 51 years of what works (and what bites) across audio, medical, industrial, and power electronics.

- Production that matches design: Master winders, documented processes, and controlled materials equal repeatability. Need UL/IEC files? We build to that path.

What we need to move fast (and how we can help if you don’t have it)

Send what you have—or ask us to reverse-engineer and fill the gaps.

- Output(s): voltage/current or impedance, regulation, ripple/noise goals

- Input: line or DC bus, frequency, duty cycle, limits

- Envelope: max footprint/height, mounting and terminals

- Environment: ambient, cooling, altitude, ingress, safety standards

- Priorities: rank size, cost, efficiency, noise, time-to-market

Don’t have exact specs? Ship a sample—we’ll measure turns ratio, DC resistance, leakage, inductance, and build a like-for-like or improved design.

Quick Application Guide for Transformer Cores

- Audio signal path: 80% Ni cores, R-core or high-grade EI for low leakage and low distortion.

- Audio power / low-hum mains: M6, thin laminations preferred; R-core when stray field must be minimal.

- General power (cost-sensitive): M27/M29/M36; consider M50 if losses are acceptable.

- Chokes/gapped inductors: Non-oriented steels (M27–M36–M50) handle multi-axis flux; ferrite for higher-frequency ripple.

- SMPS magnetics: Ferrite families matched to switching frequency and temperature profile.

Custom-Designed Transformers from Experts in Custom Magnetic Components

Off-the-shelf, general transformer design works when the circuit is forgiving. When performance, size, noise, compliance, or reliability are non-negotiable, a custom transformer saves debug cycles—and often total system cost. After 50+ years, we know which levers to pull and how to build what we design.

Ready to talk through your specs? Send a schematic and envelope—or a sample to reverse-engineer—and we’ll outline a design and prototype plan.