Linear Power Supplies vs. Switch Mode Power Supplies (SMPS): Picking the Right Tool for the Right Application

The electronics industry has seen major shifts in power supply design, with switch-mode power supplies (SMPS) taking the lead in many applications due to their efficiency, compact size, and versatility. However, linear power supplies—often referred to as “wall warts”—continue to play a critical role in sectors that demand low noise, reliability, and power stability.

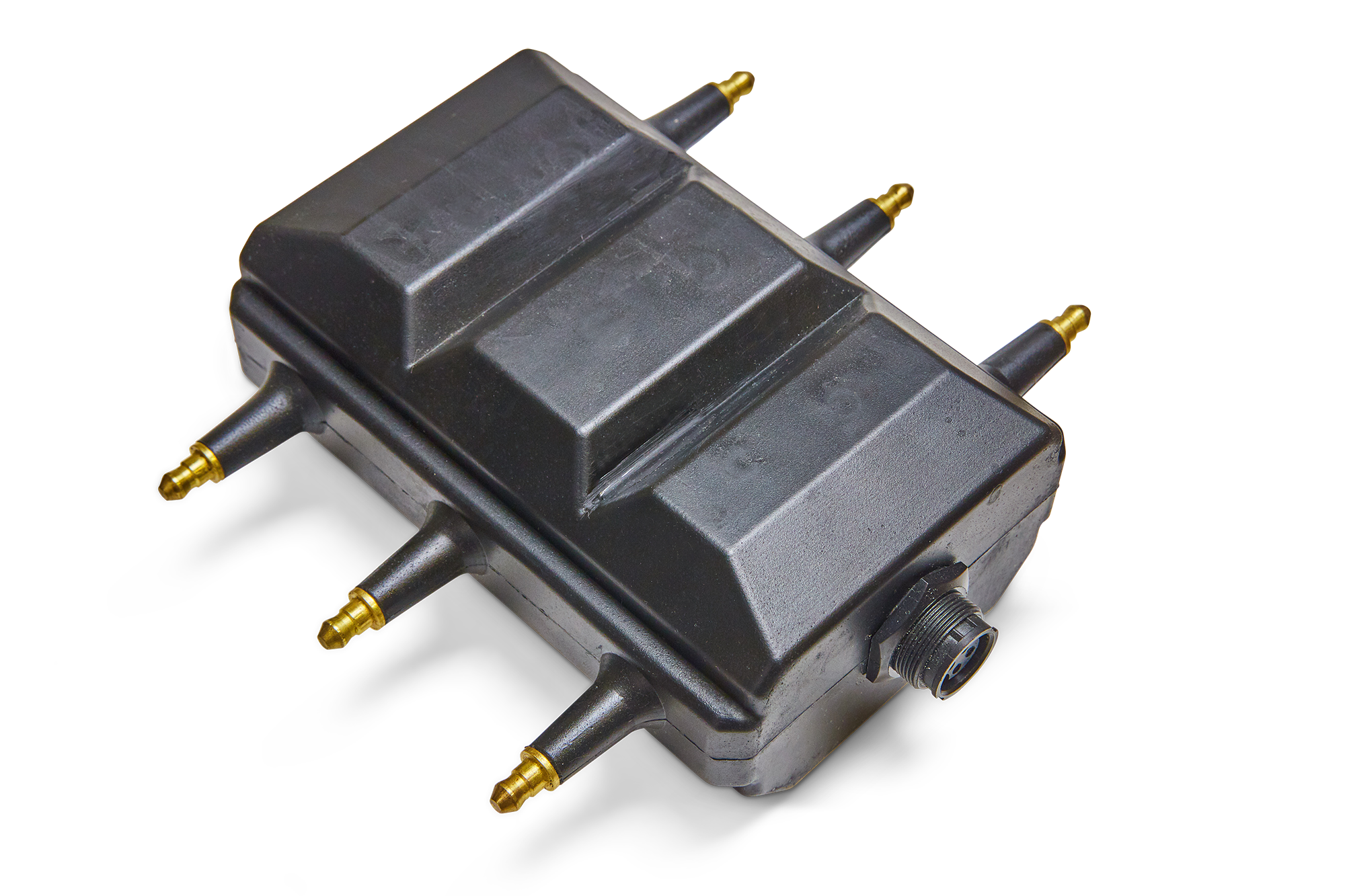

As a leading magnetics manufacturer, Custom Magnetics designs and fabricates the critical components found in both linear power supplies and SMPS, including PCB-mount transformers, toroidal inductors, and power transformers. The question is not about choosing one over the other—it’s about selecting the right tool for the job.

Where Linear Power Supplies Excel

While SMPS offer advantages in efficiency and weight, linear power supplies still hold a strong position in certain applications where their unique benefits shine:

- Ultra-Low Noise: Linear power supplies provide clean, stable DC output with minimal electromagnetic interference (EMI), making them the preferred choice for audio processing, medical devices, and precision instrumentation.

- Reliability & Simplicity: With fewer components and no high-frequency switching, linear power supplies have long lifespans, predictable performance, and straightforward maintenance.

- Superior Load Regulation: Linear power supplies excel at maintaining voltage stability, making them well-suited for test equipment, sensors, and communication systems that demand accuracy.

- Rugged & Durable: Unlike SMPS, linear power supplies do not require complex switching circuitry, making them less susceptible to transient failures and more resistant to harsh operating conditions.

For applications that prioritize low noise, stability, and durability over size and efficiency, a linear power supply remains the best choice.

Where SMPS Take the Lead

SMPS technology has rapidly advanced due to its efficiency and design flexibility, making it ideal for:

- High-Efficiency Power Conversion: By operating at high frequencies, SMPS minimize energy losses, reducing heat dissipation and improving overall system efficiency.

- Compact Designs: SMPS require smaller transformers and components, making them a better fit for space-constrained applications like portable devices and embedded systems.

- Global Compatibility: With the ability to handle a wide range of input voltages, SMPS are ideal for devices that must operate across multiple power grids.

- High-Power Applications: From industrial automation to DC motors and aerospace systems, SMPS handle high power levels efficiently without excessive weight or heat.

When you’re looking for a compact and powerful package, SMPS are the way to go.

Choosing the Right Power Supply for Your Application

Rather than thinking of SMPS as a replacement for linear power supplies, it’s more accurate to view them as complementary technologies. The decision should be based on your specific application requirements:

| Application | Best Choice | Why? |

| Audio Equipment | Linear Power Supply | Eliminates EMI noise, ensuring distortion-free sound. |

| Medical Equipment | Linear Power Supply | Reliable, low-noise power for sensitive electronics. |

| Precision Testing & Instrumentation | Linear Power Supply | Provides stable, accurate voltage with minimal ripple. |

| Industrial Automation | SMPS | High efficiency and compact form factor. |

| Aerospace & Defense | SMPS | Lightweight, high-power output with global compatibility. |

| Data Centers & Servers | SMPS | Minimizes heat and power loss in high-density environments. |

| Telecommunication | SMPS | Depends on the sensitivity of the signals and power needs. |

Looking to the Future

While linear power supplies have seen improvements in core materials, insulation, and efficiency, SMPS technology continues to evolve. However, concerns over the recyclability and environmental impact of SMPS components have renewed interest in simpler, more sustainable linear power solutions.

Final Thoughts

Both linear power supplies and SMPS have their place in modern electronics. Engineers should select the right tool based on application needs rather than defaulting to one technology over the other. And no matter which technology you choose, magnetic components remain at the heart of every power conversion system.

At Custom Magnetics, we specialize in designing and manufacturing the transformers, inductors, and coils that power both linear and switch-mode power supplies. If you’re designing a new prototype or production run, let Custom Magnetics help you optimize your power system. Whether you need a high-frequency PCB transformer for an SMPS or a precision-wound power transformer for a linear supply, we’re here to assist you in creating the best solution.

Visit our website to request a quote or speak with our design team today.