Inductors are everywhere — from phone chargers to data centers to EVs. But not all inductors are the same. The two main families are air-core (no magnetic material inside) and magnetic-core (using materials like ferrite or powdered iron). Each has trade-offs in size, efficiency, frequency, and cost. Here’s a practical breakdown to help you choose the right type for your application.

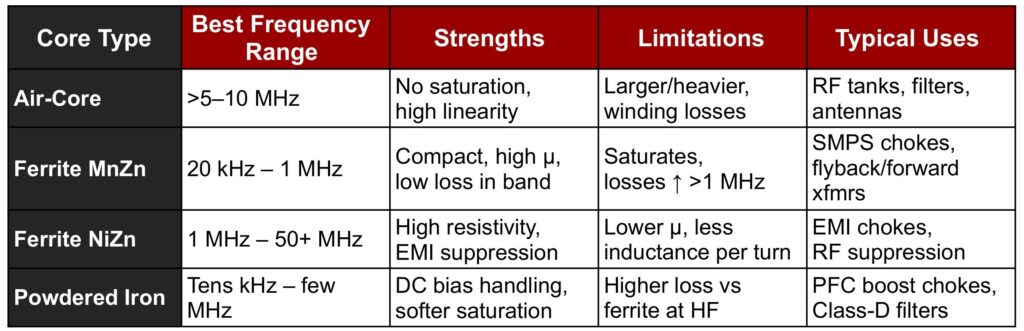

Air-Core Inductors

An air-core inductor is simply a coil of wire — sometimes wound around a plastic form, sometimes just the wire itself. There’s no magnetic material inside.

Strengths

- Excellent for very high frequencies (>5–10 MHz).

- No risk of magnetic saturation.

- High linearity (performance doesn’t shift with signal level).

Trade-offs

- Require more turns of wire → usually larger/heavier than magnetic-core types for the same inductance.

- Winding resistance and parasitics (skin/proximity effects) limit efficiency at high current.

Common uses

RF filters, antennas, precision circuits, fast gate-drive snubbers.

Magnetic-Core Inductors

Ferrite (ceramic oxides)

- MnZn ferrite: Best from ~20 kHz to 1 MHz (e.g., switch-mode power supplies).

- NiZn ferrite: Best from ~1 MHz up to 50+ MHz (e.g., EMI suppression chokes).

Strengths

- High inductance in a compact size

- Lower copper loss than air-core.

Trade-offs

- Saturation current limits.

- Losses rise quickly outside the sweet spot.

Powdered Iron (distributed gap)

- Works well from tens of kHz to a few MHz.

- Handles heavy DC bias and ripple currents (e.g., PFC boost chokes, Class-D output filters).

- “Soft” saturation curve — more forgiving than ferrite.

- Higher core loss than ferrite at higher frequencies.

Laminated Silicon Steel

- Used at 50/60 Hz in transformers and large inductors.

- Not practical for high-frequency inductors.

Quick Comparison Table

Selection Checklist

When picking an inductor, consider:

- Frequency: Fundamental + harmonics.

- Current: RMS (thermal) and peak (saturation).

- Losses: Copper (DCR, skin/proximity) vs core (material loss).

- Form factor: Shielded vs open, toroid vs bobbin, size constraints.

- Environment: Temperature range, altitude, safety approvals.

Don’t have all the answers? That’s okay. Many of our customers just bring us:

- A schematic, or

- The part they’re currently using, or

- A performance requirement (e.g., ripple current, frequency, size limit).

From there, we can reverse-engineer an existing part or build a new design around your requirements.

Custom Manufacturing at Scale

Every part we make is custom — nothing off the shelf

- We take orders as small as 5 pieces, but custom materials (bondable wire, Litz, high-temp bobbins, custom-tooled bobbins, etc.) are more cost-efficient at larger volumes (100, 500, 1,000+).

- If you only need 5 pcs, we can deliver — but setup costs are naturally spread over fewer units.

- For production, we can scale to thousands with consistent quality.

Why Choose Custom Magnetics

We don’t just select parts from a catalog. At Custom Magnetics, we:

- Run calculations based on your schematic or your requirements.

- Select the right material (air, ferrite, powdered iron).

- Prototype, test, and iterate.

- Deliver production-ready inductors, wound by master winders with full documentation.

Ready to start? Send us your schematic, requirements, or even the part you’re using today. We’ll do the rest. Contact Us or Request a Quote