Manufacturing Excellence in Transformers

Custom Magnetics, Inc. manufactures custom power magnetics for use in a variety of applications, including audio amplifiers, intercoms, voice and music reproduction equipment, test/measurement instruments, telephone communication networks, transducers, lighting systems, and industrial controls.

Using our engineering teams’ carefully laid-out designs, we manufacture your product with precision and pride in approximately 40,000 square feet of air-conditioned production and office space. In addition, our well-trained workforce can fast deliver small- to medium-volume orders.

A Wide Range of Winding Capabilities

A Wide Range of Winding Capabilities

Custom Magnetics uses the latest manufacturing equipment to perform various processes.

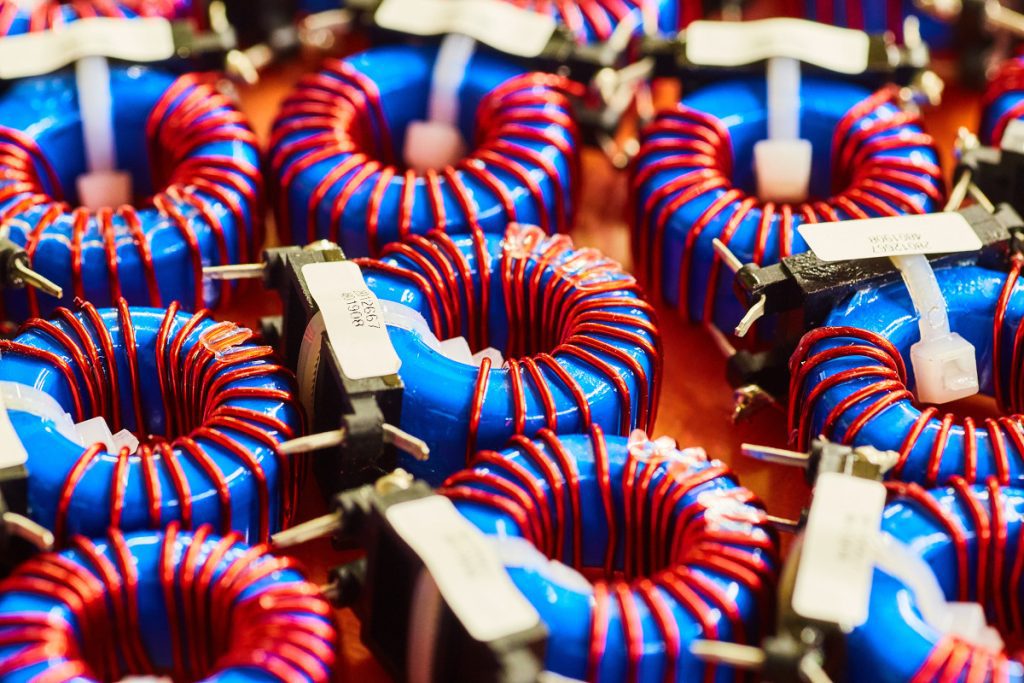

Toroid & Programmable Winding Machines

Our precision toroidal winding technology ensures transformers with exceptional efficiency and minimal EMI, delivering consistent electrical properties and unmatched reliability for your most demanding projects.

R-Core Winders

Custom Magnetics’ R-core transformers are designed for high-efficiency and low-noise applications. Their unique shape minimizes magnetic leakage and reduces core losses, making them ideal for laboratory instruments, high-fidelity audio equipment, and precision electronics where stability and performance are critical. Their superior design also allows for compact, space-saving configurations without compromising energy efficiency.

Ferrite Cores

Due to their low eddy current losses, Ferrite cores (such as pot cores, EE cores, and toroids) are ideal for high-frequency applications. Their use ensures efficient energy transfer, reduced interference, and optimal performance in compact designs, making them superior to other core types in high-frequency environments.

Silicon Steel Cores

Silicon steel cores (EI cores, C-cores, and laminations) are ideal for low-frequency and power applications due to their high permeability and low hysteresis losses. Their use ensures efficient energy conversion, reduced core losses, and reliable performance in power transformers and inductors, making them a preferred choice for applications requiring stable operation at low frequencies

Other Equipment Capabilities

In addition, we also have a wide range of additional equipment:

- Multiple-Layer Winders

- High-Speed Bobbin

- Automatic Lamination Stacking Machines

- Vacuum Impregnation Tanks

- Baking Ovens

- Computerized Test Equipment

Our Manufacturing Process

Our custom current sense transformers can be built to meet varying customer specifications, including extreme operating conditions (such as temperature, radiation, or humidity) and current ratio, output, and capacitance requirements.

The North Manchester facility can produce 50/60/400 Hz transformers up to 1,000 VA and ferrite transformers for frequencies up to 250,000 Hertz.

Expanding and Improving

Expanding and Improving

During the 1990s, we began developing higher-volume production capabilities with our joint venture partner in Borada, India. This modern facility has proven to be a reliable partner, able to produce large-volume orders at low cost, enabling us to deliver your product even quicker. The India facility also exports large oil-filled distribution transformers up to 2000 KVA in size.

We didn’t stop there. Custom Magnetics has continued to strengthen its manufacturing capabilities, with its experienced and highly skilled workforce and the latest technology and equipment.

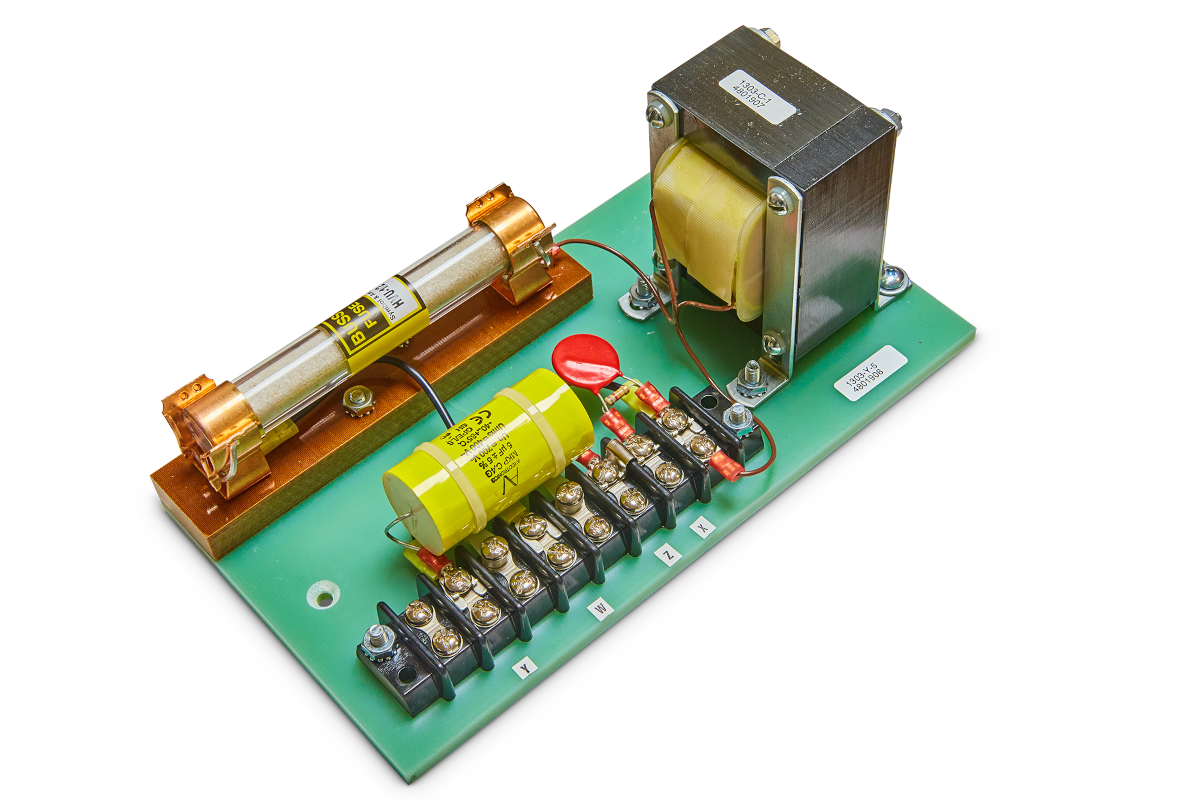

Turnkey Assembly

Custom Magnetics also offers turnkey assembly for your finished products. We can procure all components and completely assemble the finished product, simplifying your manufacturing process.

Whether you need custom power transformers for one-off, low- or medium-volume component quantities, Custom Magnetics has the design and production capability to suit your needs. As an ISO 9001:2015 certified company, we ensure that everything we produce is tested regularly during manufacturing and is of the highest quality and reliability.