Transformers play a crucial role in power management across the globe, in every electrical system and electronic device. As systems for capturing renewable energy have made a firm stance globally, especially with growth, be it solar arrays or wind farms or another system, so too does the need for transformer designs that can handle the unique requirements of renewable energy.

Why now?

Renewables supplied a record ~32% of global electricity in 2024, up from ~30% in 2023, and are on track for ~46% by 2030,with solar and wind doing most of the lifting (Reuters; IEA Renewables 2024; IEA Global Overview 2024). For that growth to translate into reliable megawatt-hours, the small transformers inside the inverter—the 1–100W parts that power control, gate drive, sensing, fans, and comms—have to be efficient, quiet, and durable.

What’s different inside the inverter: A Quick Overview

- Lives next to fast switching: Provide safe isolation (creepage/clearance per your UL/IEC route), keep interwinding capacitance reasonable so the control side stays quiet, and hold spec at real enclosure temps.

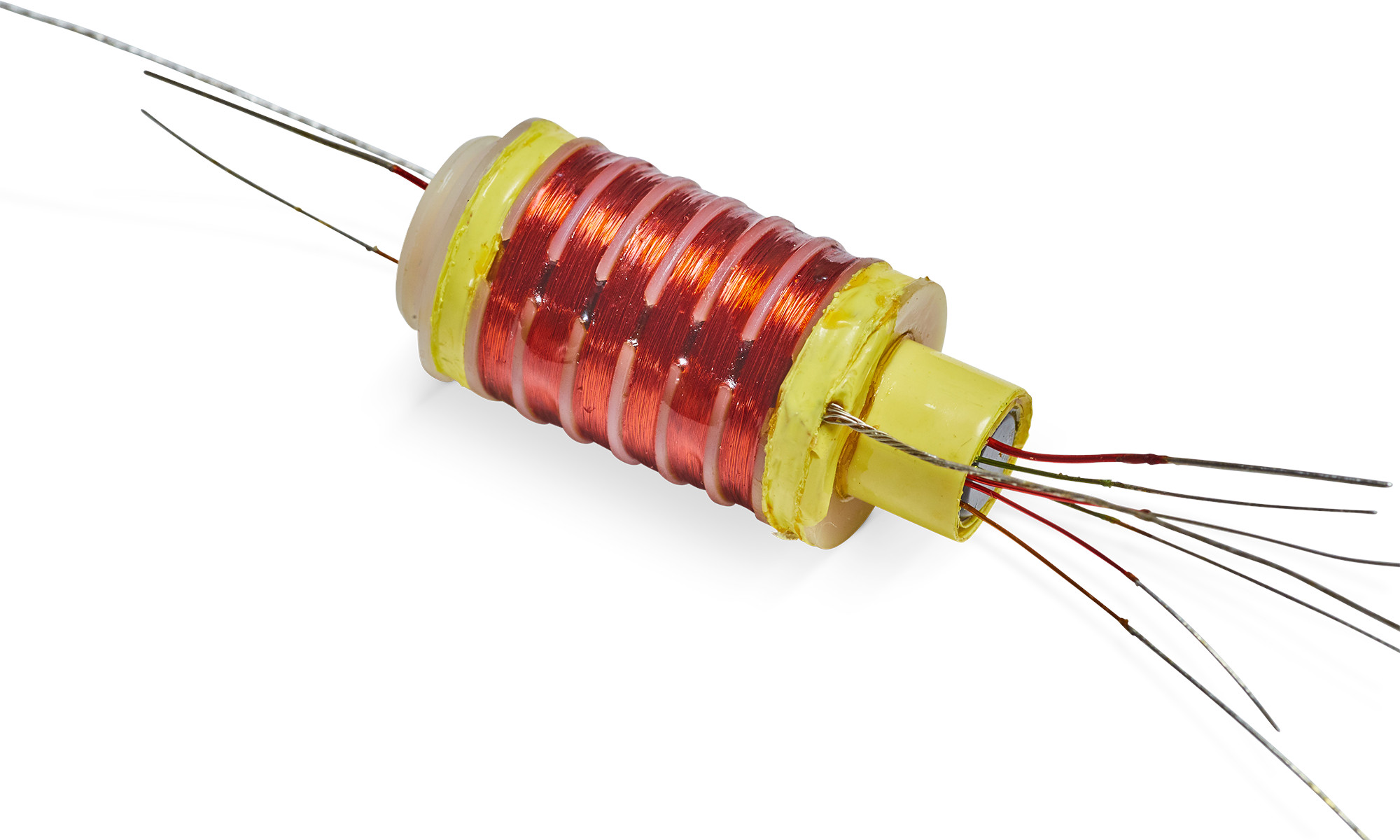

- Efficiency without heroics: Efficiency typically is harder to achieve from renewable energy sources. Smart choices on core size, turns, and wire gauge often beat exotic builds. (We can do Litz/foil when a design truly needs it, but many robust auxiliaries succeed with conventional round wire—e.g., toroids—when frequency, ripple, and thermal paths are right.)

- EMI is a team sport: Layout, shields, and the surrounding filters matter as much as the transformer. Early coordination saves weeks later.

- Field conditions still apply: Vibration, condensation, and wide ambientes are normal. Impregnation/varnish, stable plastics, and corrosion-resistant terminations buy long life.

A simple spec that gets you a fast, accurate quote from Custom Magnetics

- Function: Aux flyback / LLC, gate-drive isolation, or current sense

- Power & Frequency: Target watts + switching range

- I/O: Voltages, currents, and any regulation notes

- Isolation: Basic/reinforced, test voltage, UL/IEC path

- Fit: Max footprint/height or “fits in: __ × __ × __ mm”

- Environment: ambient/airflow/enclosure clues

- Additional (and Useful) Specs: EMI pain points from prior revs; preferred pins/leads

- Quantities & Dates: Samples + first builds window

If something’s unknown, say so! We’ll help you converge without locking you into a risky path.

What Custom Magnetics offers for Inverter OEMs

- 5–60W flyback and 40–100W LLC auxiliaries

- Gate-drive transformers (low interwinding capacitance, good balance)

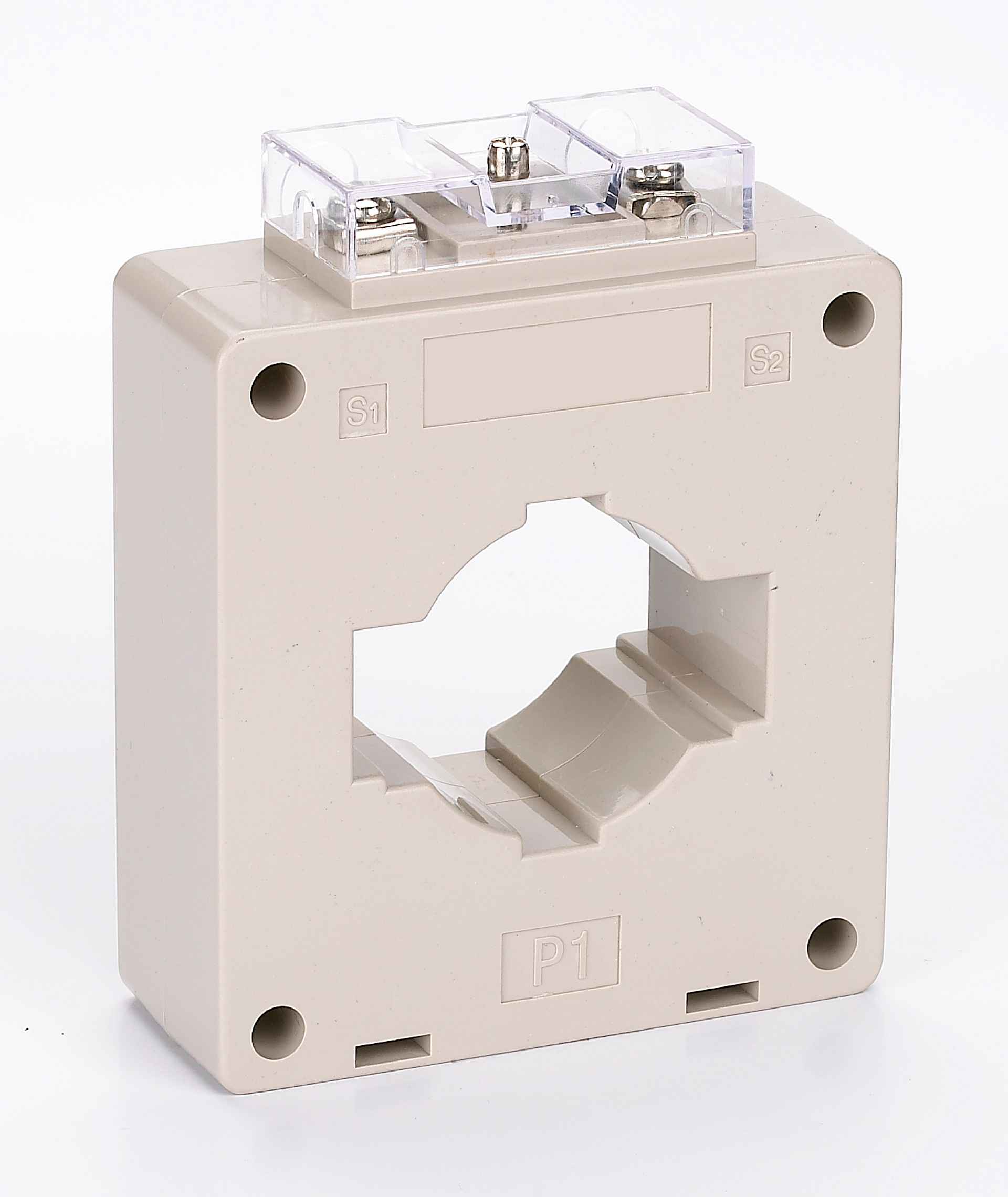

- Current-sense transformers for phase/primary measurement

- CM/DM chokes tuned to your emissions mask and layout constraints

Supporting Your Program with Expert Design and Production

- Prototype to Production Under One Roof: We design and mass-produce 5 to 20,000 parts from North Manchester, IN, with consistent materials and processes from design to delivery.

- Factory-Ready Documentation: First Article Inspection, drawings, test limits, and tolerances aligned with your UL/IEC review and what our line actually measures (inductance @ test current/freq, DCR, turns ratio, leakage, HIPOT/PD).

- Lifecycle Continuity: If a later rev changes frequency or rail currents, we adapt the same form factor so your PCB and mounting stay fixed.

Custom Magnetics, Inc: Your Source for Custom Transformer Designs

Custom Magnetics, Inc. designs and manufacturers custom transformers for a wide variety of applications, including distribution, power, and step-up/step-down transformers used in solar, wind, hydropower, and geothermal energy systems. Contact Custom Magnetics today with your specifications, design concepts, application requirements, and any other details or questions that you may have–we’d be happy to help you with your next project!